Quality and environmental sustainability.

Our primary objective is to provide effective support to our partners in the fish processing industry, while taking environmental factors into consideration. Because we exclusively process fish scraps, this helps to conserve valuable fish resources. Our activities extract maximum benefit from catches made by the fishing industry.

All processes and product developments reflect this philosophy. All processes and products are subject to strict quality standards and checks, starting on receipt of the raw material. Stringent tests carried out in our own laboratory and by independent third-party laboratories with the relevant certification ensure that only products of appropriate quality are distributed/delivered.

Further tests are carried out during the production process. Our products also undergo regular testing for pathogens and other unwanted substances. We cooperate with public authorities, scientific institutes and universities to raise product quality and to minimize related risks. Several Bachelor, Master and PhD thesis have been successfully carried out at Bioceval.

We collect the leftovers.

As a special service we provide insulating containers approved for use in the food industry and (for large quantities) special large containers which enable leftovers from processing to be presorted by species. Collections are made by established and approved transport companies which are subject to strict, regular control.

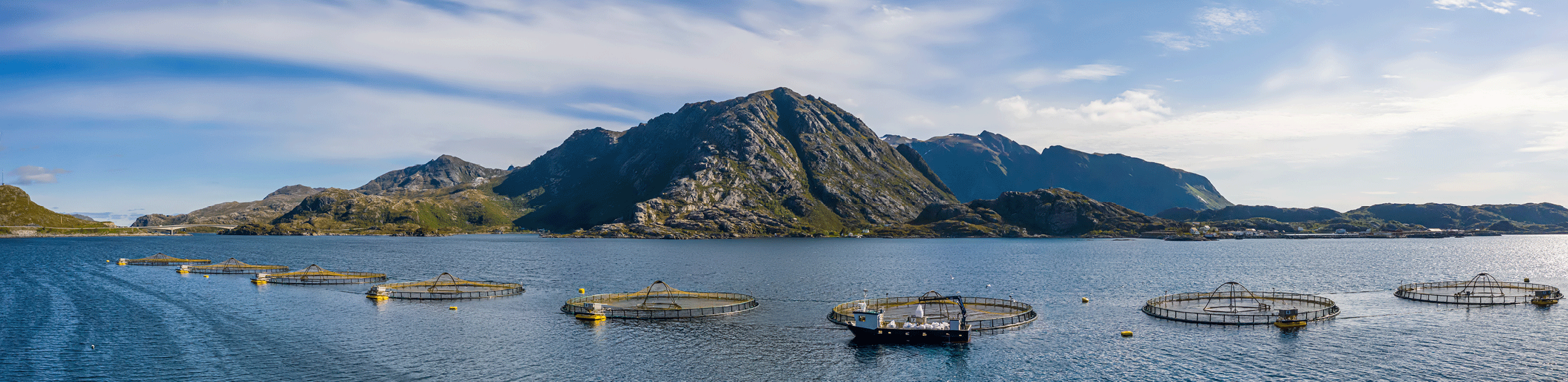

The raw materials we use include scraps from marine fish from fishery (pollock, rosefish, plaice, herring, etc.) and from farmed fish (salmon, trout, etc.).

How to obtain quality oil and unmixed meal.

Bioceval has two high-capacity production lines and a small product line for manufacturing special fish meals and fish oils. On delivery, raw materials are checked for quality before storing according to type in special bunkers. During the subsequent production process, the raw material is heated, pressed, deoiled concentrated and finally dried, . The production process results in high-quality oil and meal.

A history of growth. And prospects for more.

High-grade fishmeal and fish oil from Cuxhaven have a long lasting tradition. Already in 1938, there have been three fishmeal plants in Cuxhaven:

- The “Cuxhavener Fischmehl- und Dampfwerke GmbH“ (Cufida – mainly owned by “Nordsee Deutsche Hochseefischerei GmbH“)

- The “Deutsche Fischmehlfabrik Lohmann & Co.”

- The fishmeal plant from “Hussmann & Hahn“

In the 70s “Cufida” was transformed into a division of “Nordsee” and operated under the name of “Nordsee Deutsche Hochseefischerei GmbH”. The fishmeal plants “Hussmann & Hahn” and “Deutsche Fischmehlfabrik Lohmann & Co.“ were combined to form the “Vereinigte Fischmehlwerke Unterelbe GmbH & Co. KG”.

On 17th January 1983 the “Vereinigte Fischmehlwerke Cuxhaven (VFC)” started their work. We were established by the merger of “Vereinigte Fischmehlwerke Unterelbe GmbH & Co. KG” and “Nordsee Deutsche Hochseefischerei GmbH”. Since 2004 we are incorporated into the European network of the SARIA group. In 2015, the former company name changed in the course of a European internationalization in Bioceval. As long as our company exists, we have worked on enriching our products by focusing on speciality products. Due to our sorted raw material we have the possibility to not only produce standard fish meal and fish oil but also special salmon-, trout-, white- and shrimp meal, as well as salmon oil.

With its 25 years of experience in the production of fish meal and fish oil and the Europe-wide presence of the SARIA Group, the Bioceval is set for future developments.

The Vereinigte Fischmehlwerke Cuxhaven formed by the merger of our predecessors in 1983. In 2015, the former company name changed in the course of a European internationalization in Bioceval.

You would like to know more about our work?

Then please contact us. We look forward to your feedback.

E-Mail: info@bioceval.de | Phone: +49 4721-70 73-0